Experienced, qualified Master Saddlers and highly-skilled model makers combined their talents to translate the principles of a traditional tree into a computerised design programme.

Experienced, qualified Master Saddlers and highly-skilled model makers combined their talents to translate the principles of a traditional tree into a computerised design programme.

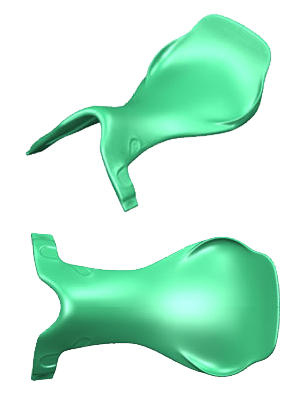

To ensure every tree is symmetrical, the exact measurements of one side were digitised and then mirror-imaged to produce the other side.

This digitised data is then used to accurately cut each mould for every tree design and size from one solid block.

The insides of the moulds are hand-finished to achieve a perfect finish.

High-pressure injection moulding machines are then able to produce consistently identical trees, eliminating the possibility of variations in shape or symmetry which might occur in the traditional handmade equivalent.